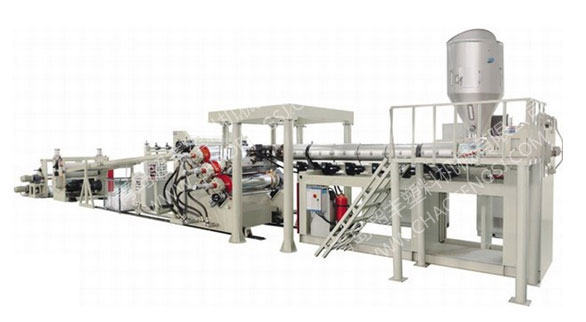

Product description

The main advantages of the continuous production equipment of the carat tube:

1, do not need to buy different specifications of the mold - low investment costs and less space

2, molding mold does not require natural gas baking - energy saving

3, no need to change the mold - workers save high efficiency

4, continuous production - high efficiency

5, pipe length 1 to 17.5 meters - low transportation costs

6, the socket cutting is carried out at the party temperature - low shrinkage, good welding and sealing

7. Pipes with a diameter of 800mm or less can be hot-melt welded - reducing the trimming process

The carat tube is the only high-quality pipeline with no pipe accidents in China for 10 years. The application fields are municipal drainage, sewage discharge, nuclear power, culvert, chemical storage tanks and so on.

The company combines German gram to take over production equipment, integrates domestic diversified winding equipment, and has been researched and developed for 2 years. It successfully trial production in 2014. The diameter of the equipment produced by the equipment is 300-3500mm in diameter, and the quality meets the national GB/T19472.2-2004 standards. The continuous production equipment of our company's carat tube has no fire baking mold, dynamic demoulding, continuous production, socket One molding, the length of production can be customized according to the length of the transport vehicle, etc. The advent of this equipment will fill the gap in the international market.

Position:

Position:

![[product:P_title] [product:P_title]](/upLoad/product/month_1808/201808231652569248.jpg)