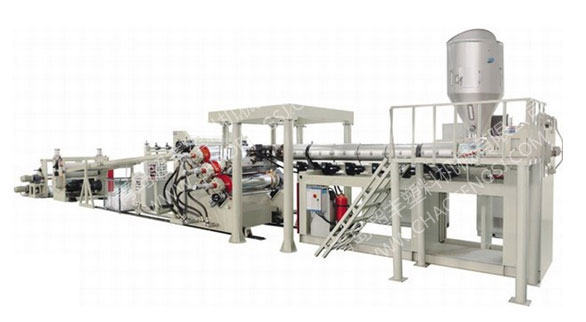

※ The special single-screw extruder for polyolefin is equipped with high-speed extrusion and high-speed speed.

※ The special separation type mixing screw and spiral structure head have reasonable flow path and smooth inner and outer walls of the pipe.

※ Specially designed sizing cooling method: the production range is 50-200mm, and the production speed is as high as 0.6-1.5m/min.

※ Standard designed pipe head

※ Spiral distribution type of fluid, large flow space, to ensure that the melt has sufficient residence time.

※ The optimal design of low melting temperature, the internal stress of the pipe is small, and the inner and outer surfaces are smooth.

※ High flexibility, suitable for co-extrusion of all polyolefin materials, can be extruded in two layers, three layers of spiral reinforced tubes of different specifications.

※ The optimized design of the copper spiral sizing sleeve has a pre-cooling device and a powerful vacuum suction device at the inlet end, which is suitable for high-speed extrusion of the pipe.

※ Specially designed sprinklers provide efficient spray cooling.

※ Longitudinal movement motor adjustment, three-dimensional adjustment can be realized up and down and left and right.

※ The cabinet is made of stainless steel.

※ High efficiency pumps and special sprinklers provide efficient spray cooling.

| Extruder | SJ-90/30B | SJ-65/30B |

| Machine head | ф50-200 | ф50-125 |

Sizing tank | SGZL-200 | SGZL-125 |

| Tractor | SLQ-200 | SLQ-200 |

| Winding machine | SQ-200 | SQ-200 |

Position:

Position:

![[product:P_title] [product:P_title]](/upLoad/product/month_1808/201808231647094626.jpg)