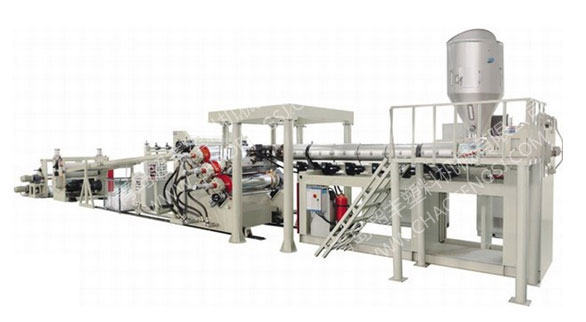

Pipe introduction

HDPE large-diameter gas/water supply pipe production line HDPE large-diameter gas/water supply pipe has excellent hardness and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress crack resistance, creep resistance, thermal connection, etc. . As a result, they have become the product of choice for suburban gas transmission and water supply pipes, playing a very important role in urban gas and water supply pipeline systems.。

Production line features

HDPE Large-diameter gas/water supply pipe production line is a new pipe production line developed by FRIEND company by absorbing recent advanced technology. It is suitable for high-speed extrusion of PE, PP, PB, PERT, ABS and other raw materials. The line has a beautiful appearance, high degree of automation and stable and reliable production. The production line is well received by customers and is the best choice to replace the advanced imported production line.

The high-speed and high-efficiency extrusion single-screw extruder is specially designed for the extrusion of PE raw materials, equipped with low-noise fans and high-speed hard-toothed gearboxes. Special slotted feed sleeves with oil-cooled systems increase compressibility and increase fillability, which increases extrusion. High-yield screw special design, low temperature melting, good plasticizing effect, good energy saving effect.

The spiral splitting extrusion die is specially designed for the extrusion of PE raw materials. The unique low-pressure flow path spiral or blue die design ensures the low temperature and high plasticizing extrusion of PE pipe, and the specially designed mold core spiral temperature. The control ensures the good performance of the PE pipe; for different raw materials, the multi-layer co-extrusion die has the characteristics of low layer structure cost and low elasticity. The easy adjustment and uniform extrusion characteristics of the mold ensure uniform melting pressure and flow, and the appearance of the pipe is even and smooth.

Marking line: The pipe marking line is extruded by a small single screw extruder through a composite die.

Vacuum sizing tank: equipped with two-stage vacuum system (for large diameter pipe), advanced water circulation, high pressure cooling system, vacuum adjustment device and precise water temperature and water level automatic control system. The precise tin bronze sizing sleeve has the characteristics of fast cooling of the pipe and fast setting. The water tank is made of stainless steel.

Spray Cooling Water Tank: The long cooling system ensures efficient cooling of the pipe and the unique piping system reduces the cooling length. The water tank is made of stainless steel.

Tractor: The special integral transmission avoids the asynchronousness of the independent drive. Different control modes ensure flexible and precise positioning and orientation, and the precise pressure regulation system can adjust the traction. The device has a unique structure and flexible operation, and the variable frequency motor can adjust the traction speed of the device.

Cutting machine: The full hydraulic design of the cutting machine guarantees flexible pressure during cutting, flexible adjustment of the blade position and cutting depth. The unique power input system guarantees the reliability of planetary cutting. The low noise and powerful suction system and the unique chipless cutting device ensure chipless cutting of 16mm-315mm tubing.

Control system: One of the most advanced control systems of plastic machinery - PLC control system, which guarantees high quality extrusion of equipment. The PLC control system guarantees high-speed extrusion and high-precision, flexible control of networking functions. Intelligent control makes the line very easy to operate.

Model parameter

| Model / Parameter | Pipe Range (mm) | Extruder Model | Marking Line Extruder Model | Production Speed(m/min) | Maximum Output(kg/h) | Installed Capacity(kw) | Dimensions (L×W×H) |

| FPEG-50×30-63 | Ø20-Ø63mm | FSJ-50×30 | FSJ-25×25 | 0.3-12 | 120 | 65 | 36 ×2.2 ×2.5m |

| FPEG-65×30-125 | Ø20-Ø125mm | FSJ-65×30 | FSJ-25×25 | 0.3-12 | 220 | 110 | 56 ×2.2 ×2.6m |

| FPEG-80×30-160 | Ø63-Ø160mm | FSJ-65×30 | FSJ-30×25 | 0.3-6 | 300 | 150 | 50×2.2 ×2.8m |

| FPEG-80×30-250 | Ø75-Ø250mm | FSJ-80×30 | FSJ-30×25 | 0.5-5 | 400 | 200 | 52 ×2.2 ×3m |

| FPEG-90×30-400 | Ø160-Ø400mm | FSJ-90×30 | FSJ-30×25 | 0.2-2 | 550 | 280 | 66 ×2.2 ×3m |

| FPEG-90×30-500 | Ø200-Ø500mm | FSJ-90×30 | FSJ-30×25 | 0.1-1 | 700 | 360 | 70 ×2.3 ×3.5m |

| FPEG-100×30-630 | Ø355-Ø630mm | FSJ-100×30 | FSJ-30×25 | 0.1-1 | 800 | 450 | 72 ×2.3 ×3.5m |

| FPEG-120×30-800 | Ø400-Ø800mm | FSJ-120×30 | FSJ-45×30 | 0.05-0.5 | 1100 | 560 | 76 ×2.5 ×4m |

Position:

Position:

![[product:P_title] [product:P_title]](/upLoad/product/month_1808/201808231649069070.jpg)